The first step we take in our custom jobs is to gather all the information we need to design a more-than-perfect solution for you. We’ll work closely with you and discuss all the different requirements you need and preferences you want. By connecting and working collaboratively with you, our team can confidently execute a design that is sure to work for you.

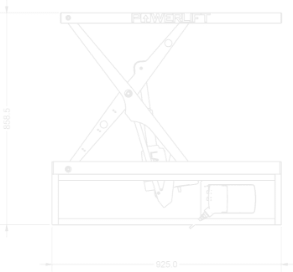

Based on our research, we’ll begin to draw up a preliminary design concept incorporating all the different factors that are relevant.

With an impressive amount of experience and expertise, no one is better positioned to provide a custom design than the team at DC Powerlift.

Once we have our design concept, we’ll share it with you for review and feedback. Based on your assessment and thoughts, we’ll happily go back to the drawing board to apply the revisions necessary to execute your vision and meet your specific needs. We’re not 100% happy until you’re 100% happy.

Once you are completely happy with our design concept, revisions included, and give us the approval to move ahead, we’ll set the custom design for production. We manufacture all of our products right here in Australia so we can keep a close eye on everything that happens and ensure complete quality control as we directly oversee custom production.

Depending on the size of the project, you may require a prototype for trial. Any issues are revised and refined so that it meets the brief. After we have collated all of the trial feedback and applied any potential further revisions as required, we’ll move on to creation of the final product.

After we’ve manufactured the final product and given it our tick of quality approval, your custom order is ready. We’ll ship the unit directly to you so that you and your team can enjoy reliable, efficient and simple lift functionality.