We’ll work through your requirements with you and discuss all the different needs and preferences you have.

Next, we’ll create a preliminary design concept based on our fact-finding meeting.

This design will be submitted to you for review and we’ll revise it according to your specific needs.

Once approved for production, we will manufacture the product and trial the prototype if required. Any further feedback and additional revisions will be taken on board.

As soon as we’ve perfected the final product, we’ll ship our custom creation directly to you.

Did you know you’re able to change the standard castor configuration? Normally the arrangement is two swivels, with one swivel directional lock and one total break. We’re able to customise any and all of this to suit your preferences.

Don’t want the standard synthetic castors? Let us know and we’ll replace your trolley’s castors with metal ones.

We offer Linak quick-change batteries with pendant control for incorporation in your scissor lift trolley, including full installation and fitting.

Our safety skirts, which look and operate somewhat like an accordion, can be added to your order. These prevent unwanted access to the scissor mechanism, for even greater safety.

Using 304-grade stainless steel with a brushed finish, this accessory provide a sanitary and easy to clean surface for your Powerlift purchase.

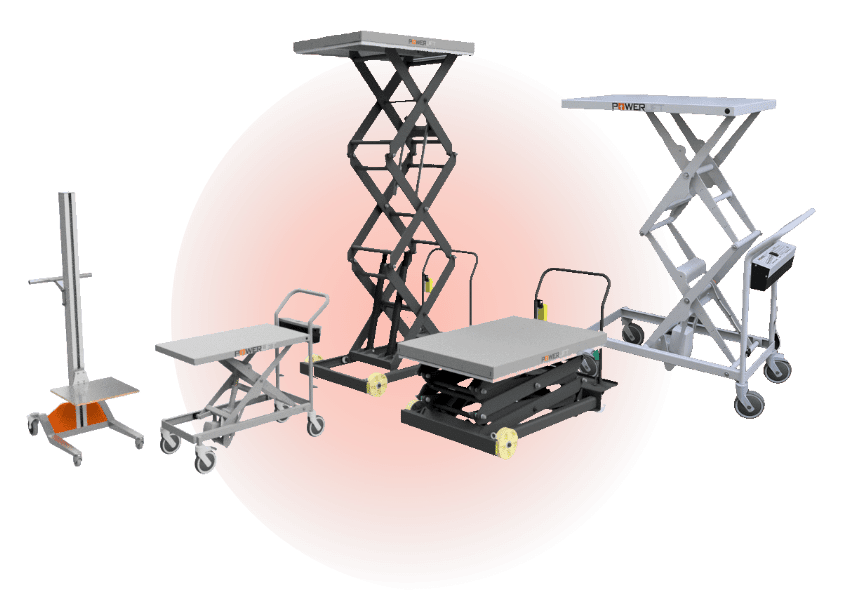

Our customers include laboratories, library and educational facilities, healthcare and aged care centres, institutional settings, clean rooms, warehouses, maintenance workshops… and the list goes on!

We’re dedicated to helping ensure your investment brings a high level of return. That’s why our products are all of the highest quality to provide assured long service life. Linear actuators are unrivalled in longevity, and failure is almost never seen.

Forget rigorous or time consuming maintenance, Powerlift products require no maintenance – just keep the batteries charged, and perform a periodic safety check.

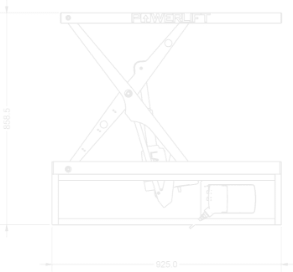

With a considered design and electro-mechanical scissor lift, you’ll enjoy reliable function every time you need to use it. Our scissor lift trolleys are significantly more reliable than hydraulic systems.

No liquid or oil means there’s no risk of a leak or spill, and no platform falling under load in the event of a burst hose.

Powerlift trolleys are quiet, and smooth to push. When lifting, the actuator is silent.

Light and easy to move, especially compared with electric-hydraulic offerings in the market, both the DC250 and DCD100 are highly mobile so you can wheel them wherever you need.

There’s no need for manual pumping – we’ve replaced this bulky operation with a push button for completely electric lifting. It’s the easy, labour-free, and simple solution.

You and your team deserve to work in an environment where risk is minimised. Our selection of table lifts help to significantly reduce the risk of injury from lifting, bending and carrying.